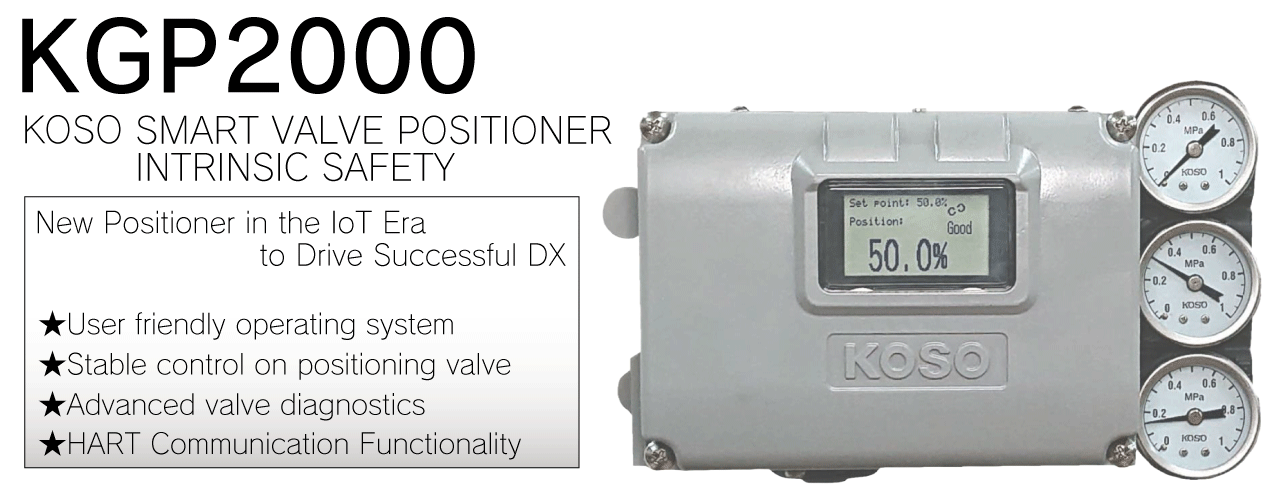

KGP2000: Smart Valve Positioner

KGP2000 series intrinsically safety smart valve positioner is a control device mounted on the pneumatic actuator for control valve, which positions a control valve according to a 4 to 20mA electric input signal from a higher-level control system or a control device.

Position feedback control system which receives feedback signal mapped to the desired valve travel and compares both input signal and feedback signal enables accurate positioning of a control valve.

In addition, it is possible to use this positioner in order to operate various types of pneumatic actuator such as linear or rotary motion actuators both of single and double acting.

Furthermore, the positioner utilizing digital techniques performs the functions of advanced PID controller, HART communication, local user interface using LCD, diagnostics utilizing sensing techniques with potentiometers.

Such features enable an easy installation and calibration, an effective monitoring and an efficient process management relevant to operations and maintenance.

It complies with equipment protection by intrinsically safety and can be safely operated in hazardous areas.

It has the same basic functions as the KGP5000 series and offers superior cost performance.

FEATURES

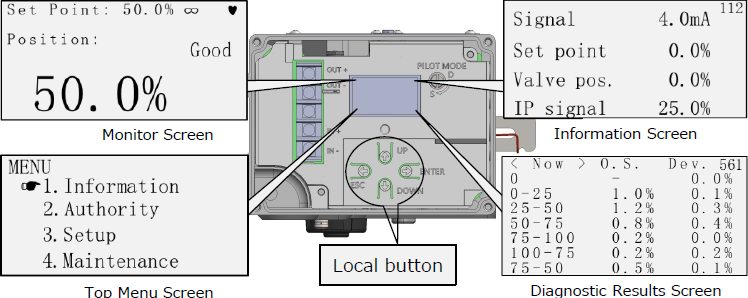

・ The use of a large graphic LCD enables a local user interface, allowing for settings, adjustments, status checks, and diagnostic functions to be performed independently on the device.

・ With the Full Auto-Tuning function, it is possible to automatically configure the zero-span settings and optimize the PID control parameters.

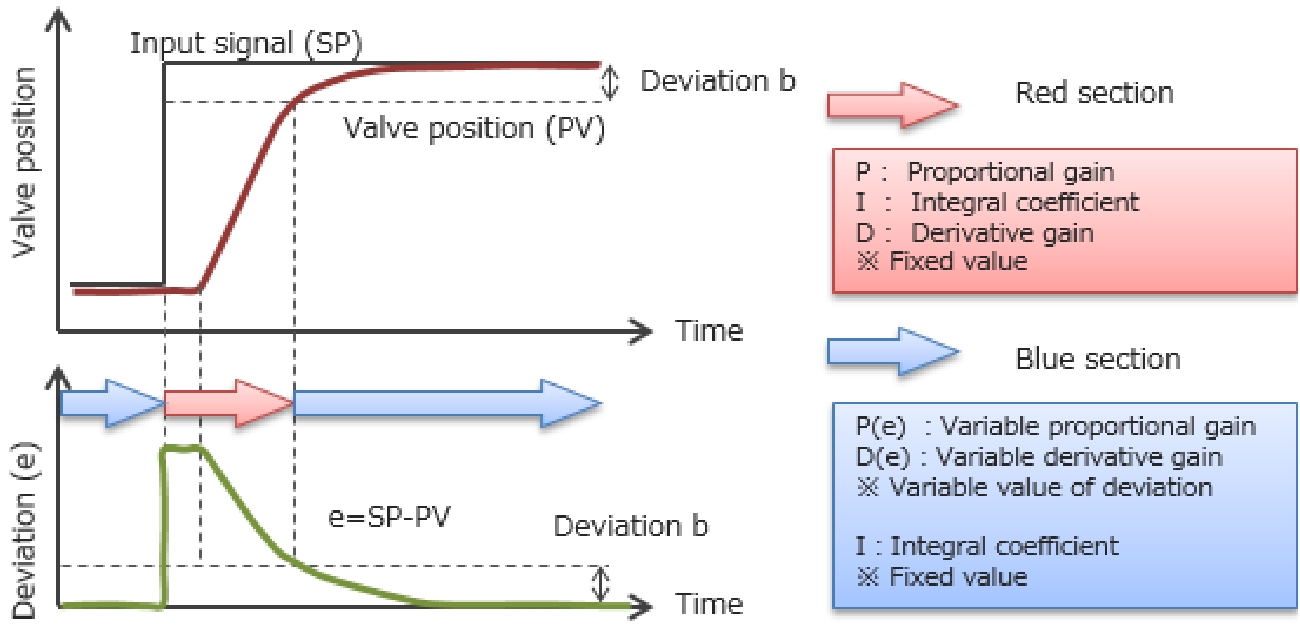

・ Adopting an Advanced Control Method that Adjusts PID Control Parameters Based on the Magnitude and Direction of Deviation.

・ Enabling Online Valve Diagnostics to Shift from Reactive Maintenance to Condition-based Maintenance.

- Total stroke

- High temperature time

- Low position time

- Total direct change

- Low temperature time

- Partial stroke time

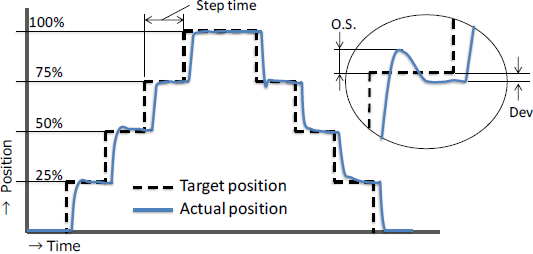

Overview of Valve Diagnosis using a 25% Step Response

A 25% step response is conducted to record the maximum overshoot(O.S.) and final deviation (Dev). By comparing the initial value, previous value, and current value, it is possible to confirm the aging changes in the step response operation.

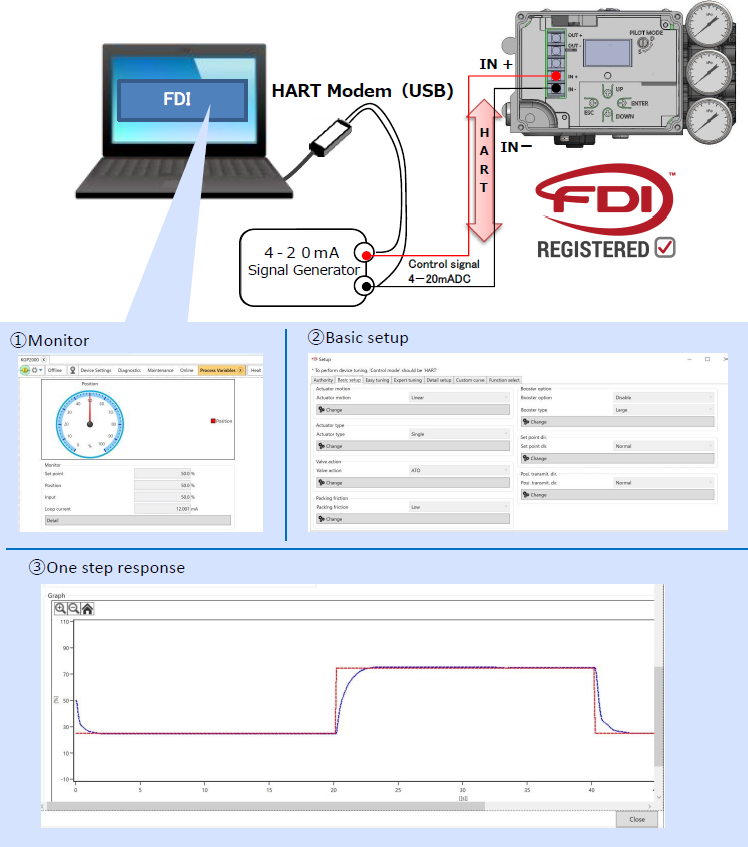

1.Monitoring of device status.

2.Device configuration and adjustment.

3.Retrieval of diagnostic data.

・ Standard Equipped with Position Transmitter Functionality

・ Applicable to Single-Acting and Double-Acting Actuator through Pilot Relay Switching

・ Structure is Intrinsic Safety Explosion-Proof Type (Non-Explosion-Proof Structure Type also available)

・ RoHS Directive Compliance (2011/65/EU,(EU)2015/863)

・ EMC Directive Compliance (2014/30/EU)

SPECIFICATIONS

| Input signal | 4~20mADC Split Range Setting Capability |

Model KGP2003A Compliance voltage <= 9.6VDC@20mA Input impedance <= 480Ohm@20mA |

||

|---|---|---|---|---|

| Output Characteristics | Linear / EQ / QO / User custom setup (19 points) | |||

| Position transmitter *Model KGP2003 only |

4~20mADC | Power supply range 17~31VDC Alarm output *According to NAMUR043 |

||

| Available actuators | Linear type / Rotary type / Type compliant with IEC60534-6 VDI/VDE3845 | |||

| Travel range | Linear | 12~250mm *Strokes above 250mm are available with special kits. | ||

| Rotary | 40~100deg | |||

| Action | Single / Double *Pilot Relay is normal only | |||

| Supply gas / Pressure | Air, Nitrogen / 140~800kPa | |||

| Structure | Housing materials | Aluminum die-casting | ||

| Painting specification | Baked acrylic painting (Standard) Baked Polyurethane painting (Heavy duty coating) |

|||

| Protection code | IP66(by TÜV Rheinland) | |||

| Pneumatic connections | Rc1/4 or 1/4NPT *Exhaust plug can be removed, connection port G3/8 |

|||

| Electric connections | G1/2 , 1/2NPT , M20x1.5 | |||

| Mounting threads | 4xM8,4xM6 | |||

| Intrinsic safety | Ex ia IIC T5,T4 | |||

| Weight | 2.2kg(Without pressure gauge),2.5kg(With pressure gauge) | |||

| Operating temperature range | Standard type | : -40~+80degC | ||

| CCC(NEPSI) Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| IECEx Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| ATEX Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| EAC Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| ECAS Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| PESO(CCOE) Explosion-proof type | T4 : -40~+80degC T5 : -40~+60degC |

|||

| LCD display | :-20~+70degC | |||

| Operating humidity range | 5~95%R.H.(non-condensed) | |||

| Air consumption | Single acting type | 6Nl/min or less@140kPa, 9Nl/min or less@300kPa *at 50% position of full travel |

||

| Double acting type | 16Nl/min or less@400kPa, 20Nl/min or less@550kPa *at balanced pressure (70% of supply pressure) |

|||

| Performance | Position control Linearity Hysteresis |

±1.0%F.S. 0.7%F.S. |

Position transmitter Linearity Hysteresis |

±0.5%F.S. 0.3%F.S. |

| Certification | Dustproof/Waterproof Protection Class | IP66 (No. AK 50531708 0001) | ||

| Explosion-proof CCC (NEPSI) IECEx ATEX EAC ECAS PESO(CCOE) |

Ex ia IIC T4/T5 Ga (No. GYJ24.1139X) Ex ia IIC T4/T5 Ga (No. IECEx NEP 23.0027X) II 1 G Ex ia IIC T4/T5 Ga (No. CML 23ATEX2668X) 0 Ex ia IIC T4/T5 Ga X (No. ЕАЭС RU С-JP.ПБ98.В.00491/24) Ex ia IIC T4/T5 Ga (No. 25-01-135839/E25-01-141069/NB0002) Ex ia IIC T4/T5 Ga (No. A/P/HQ/MH/104/8665(P625562)) |

|||

| HART Communication | HART7 | |||

| CE Marking | EMC directive(2014/30/EU) EU RoHS directive(2011/65/EU)+(EU)2015/863 |

|||

CONTACT INFORMATION

Head office TEL.81-3-5202-4300

FAX.81-3-5202-4301

change without notice.

Copyright©2017 NIHON KOSO CO.,LTD.

All right reserved.